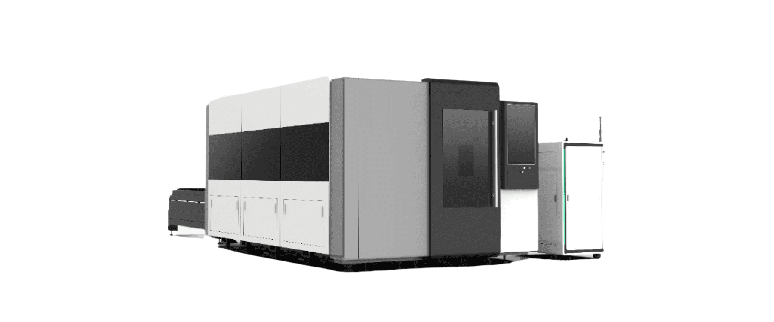

Double Pallet Fiber Laser Sheet Cutting Machine is an affordable, easy-to-use, and versatile tool that is used for high-speed cutting of metal plates

It includes

- It help us to save time and manpower of loading & unloading of material during high production. You can prepare you next sheet for cutting on the rear pallet from back side during the working of the same machine on the other pallet is going on. . Fiber Laser Cutting Machine is a boon for service industries manufacturing space under one roof, serve a variety of markets, including appliance, automotive, furniture, medical, electrical and industrial-hardware.

- Fiber Laser Cutting increases industry ability to help customers develop parts in a quicker manner, manufacturer can make multiple iterations of a fabricated part very quickly to validate a concept with customers, so it helps us in the early suppler-involvement process of part development.

- Double Pallet Fiber Laser Sheet Cutting Machine is mainly used for metal fabrication, hardware, kitchenware, electronic, automotive parts, advertising, craft, lighting, decoration, jewellery, glasses, elevator panel, furniture, medical device, fitness equipment, oil exploration, display shelf, agriculture and forestry machinery, food machinery, bridge, ship, aerospace, structure parts etc

- Fiber Laser Cutting Machine is suitable for cutting carbon steel, stainless steel, alloy steel, spring steel, aluminium, copper, brass, galvanized iron etc. It is also used during product development while meeting with customers to produce a prototype to share your ideas in visual manner. The ability to produce parts quickly is a huge advantage.

Features

- Long working life of laser source; upto 1,00,000 hours with no maintaince during usage.

- Rapid exchange between two platforms greatly improves work efficiency.

- Focal length is controlled by operating system, which has no more manual regulation, less errors or faults.

- Newest automatic calibration and cleaning functions achieve fully automatic laser head calibration and nozzle cleaning reduce repetitive manual labour.

- Small and open structure, easy operation and high cost performance.

- Fast speed,high precision cutting line, and smooth cutting edge.

- Maintenance-free operation, its cost-effectiveness is far superior than other cutting methods.